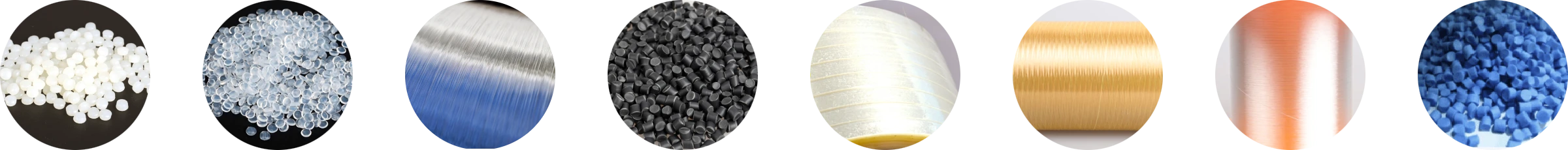

High-Frequency Wire Conductor

High-frequency wire conductors in the cable field have core advantages of low skin effect and low loss, mostly using silver/tin-plated copper alloys or stranded structures to enhance the stability of high-frequency signal transmission. With high surface finish and precise impedance matching, they reduce signal distortion. Commonly used in 5G base stations, RF cables, high-speed network cables, etc., suitable for high-frequency communications above 10GHz to meet the high-speed data transmission needs of 5G, IoT, and other fields.